What comes to mind when you hear “algae”? A green layer in a pond, or seaweeds like kelp and wakame?

Now, algae are drawing attention as materials that could support future lifestyles. At Expo 2025 Osaka, Kansai, the Japan Pavilion features algae as one of its key themes. CHITOSE’s cross-industry initiative, MATSURI, is showcasing “ALGAL by MATSURI” — a window into the future, filled with fashion, cosmetics, food, and paints made from algae.

Featured in This Interview

Mr. Tomoyoshi Kaneko

― Chief Designer, Musashi Paint

Mr. Tetsuya Akimoto

― Deputy Division General Manager, Research and Technical Development Division, Musashi Paint Holdings

Ms. Riho Shimizu

― Research and Technical Development Division, Musashi Paint Holdings

Painting the Future

Our world is overflowing with color. From smartphones and furniture to cars, buildings, and everyday items – it is hard finding something that is not painted. But what if the very base of those paints were made from algae? This idea would surprise many.

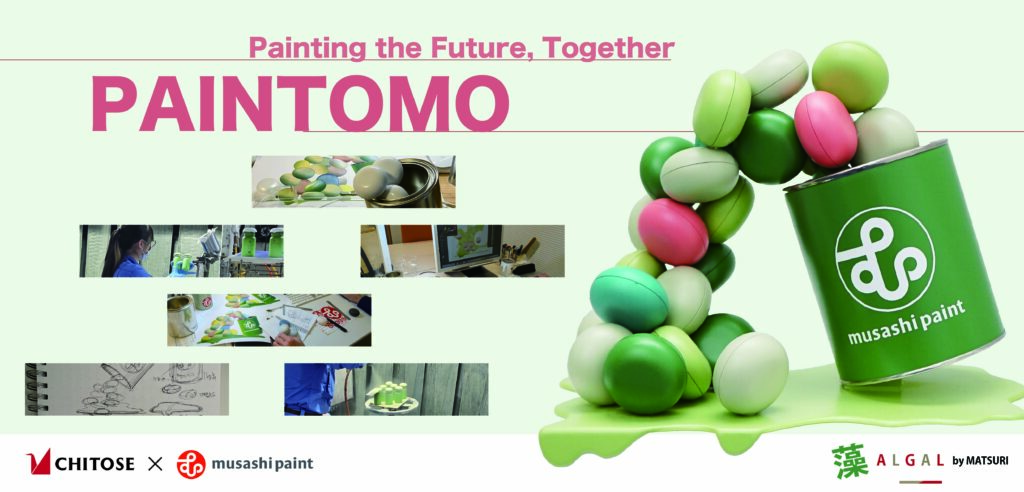

Bringing this surprise to life is PAINTOMO, an installation featured at the Japan Pavilion. In this interview, CHITOSE members spoke with Tetsuya Akimoto, who led the paint development, Riho Shimizu and Tomoyoshi Kaneko, the designer behind the exhibit.

What Does It Mean to Make Paint from Algae?

— What was your initial reaction when you first heard about an idea of making paint from algae?

Mr. Akimoto –Research and Technical Development, Musashi Paint HD:

Honestly, I was a bit confused, thinking: “What exactly are we supposed to do with algae?” But the more I learned about its properties, the more I became convinced: this material holds tremendous potential for developing paints that align with our vision of a sustainable future. Once I understood that, I thought there’s really no reason not to give it a try.

—But stepping back a bit, how does algae even become paint in the first place?

Mr. Oshima – Application Development, CHITOSE:

Paint is basically a very thin layer of plastic (resin) that sticks to the surface of an object. It’s typically made from four main components:

- Resin – forms the base film

- Pigments – adds color

- Additives – adds functionality

- Solvents – makes it easier to apply

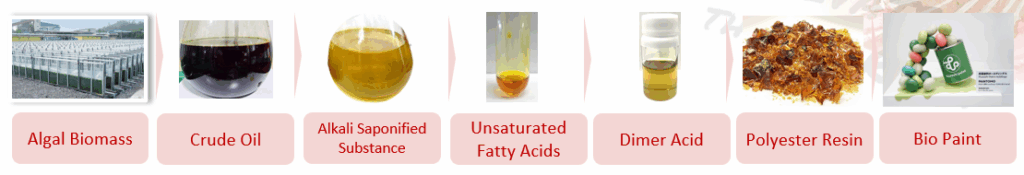

In our case, we focused on creating resin (component #1) from algae.

To put it roughly: we extract oil from algae, process it, and convert it into a resin that can be used in paint. Musashi Paint then took that algae-derived resin, blended it with the other ingredients, and developed it into what we now call “new bio-paint.”

— It seems quite complicated to turn algae into paint!

Mr. Akimoto –Research and Technical Development, :

It really is. You can try to think of it as cooking. It’s not just about throwing things together – you have to think about selecting the right ingredients, the recipe, and even the presentation. For example, if paint needs to be stronger or with more chemical resistance, we adjust the ingredients accordingly.

Once we’re happy with the ingredients, the next challenge is how to combine them. It takes multiple rounds of testing and fine-tuning before we arrive at a finished paint.

— “Selecting the right ingredients” sounds like you’re really a chef! So how does algae-based resin compare to petroleum-based or other plant-based resins?

Mr. Akimoto –Research and Technical Development, Musashi Paint HD:

The biggest difference is cost. Algae-based resin is still produced in much smaller quantities than petroleum-based ones, which makes it more expensive for now. But I believe as production scales up, the cost will naturally come down.

In terms of quality, though, we’ve been able to create something that’s nearly on par with conventional plant-based paints.

Mr. Oshima – Application Development, CHITOSE:

Musashi Paint did an incredible job of working with the limited amount of algae-derived resin we provided. They meticulously adjusted the blend with pigments and other components to create a paint durable enough for display. It is not just about mixing up bio-based materials – there’s real craftsmanship involved.

— Were there any particular challenges or surprises along the way in developing algae-based paint?

Mr. Akimoto –Research and Technical Division, Musashi Paint HD:

The hardest part was figuring out which algae to use and which components to extract for the paint. We started with designing the concept and kept experimenting through trial and error since around 2022.

Mr. Oshima – Application Development, CHITOSE:

That’s exactly why working with Musashi Paint and Tsuno Group — our resin raw material partner — and another supporting company was so essential. Everyone involved in the MATSURI project was genuinely committed and did whatever they could to move it forward. We’re deeply grateful for that support.

Paint That Reflects Future

— Ms. Shimizu, you usually work with Mr. Akimoto on development, but this time you were in charge of applying the paint for PAINTOMO. That makes you the first person in the world to ever use microalgae-based paint! Did it feel different from conventional paint?

Ms. Shimizu – Research and Technical Development, Musashi Paint HD:

That’s right (laughs). When it came time to actually apply the paint, it felt just like using regular paint. It had been perfected to a point where there wasn’t really any noticeable difference.

— The design looks quite complex. What was your reaction when you first saw it?

Ms. Shimizu – Research and Technical Development, Musashi Paint HD:

Honestly, my first thought was, “Wait… I have to paint this?” (laughs)

I wasn’t expecting it to be such a dynamic shape, so I was surprised at first. But once it was finished, I was equally surprised at how beautiful it turned out. Even from the back, you can’t see any of the joints, and seeing how the pieces I painted came together into something like this made me really happy.

— Mr. Kaneko, we heard that you were in charge of designing this piece. What inspired this impactful shape?

Mr. Kaneko –Designer, Musashi Paint:

I designed it with the image of “something new bursting out.” At first, the plan was pretty straightforward – just placing a large paint can. But I thought that felt a bit too plain, so while chatting with the CHITOSE team, someone said, “Maybe it needs a bit more movement?” And before I knew it… I was the one designing it! (laughs)

Just placing an object there wouldn’t really grab anyone’s attention and people might walk right past it. I wanted it to have that visual punch, something that would make people stop and take a closer look. And actually, the color of the paint can? According to our company manual, it’s supposed to be silver and red. But this time, we said “Let’s just do it!” and went with green, aka algae, instead! (laughs)

— Were there any challenges during the production process?

Mr. Kaneko –Designer, Musashi Paint:

At first, I was thinking of outsourcing the assembly. But then I got the estimate ― and it was surprisingly high I figured there was no way that would get approved internally. So at that point, I made up my mind to handcraft everything myself (laughs). From assembling the round parts to carving the hanging base… it was all done by hand.

— When it was finally completed, did you feel a sense of accomplishment? Or was it more like relief?

Mr. Kaneko –Designer, Musashi Paint:

Definitely a sense of accomplishment. The time between designing it and bringing it to life was incredibly short. Everyone around me was saying there’s no way this will be done in time (laughs).

Mr. Akimoto –Research and Technical Development, Musashi Paint HD:

To be honest, as of February, the paint formula hadn’t even been finalized yet. From there, we had to mix the base colors to match the exact hues of the design, while also adjusting the finish, because too much gloss would make scratches more visible.

Mr. Kaneko –Designer, Musashi Paint:

The schedule was tight and nerve-wrecking, but the moment it all came together we were over the moon!

— What does it mean for Musashi Paint to exhibit at the Expo?

Mr. Akimoto –Research and Technical Development, Musashi Paint HD:

Exhibiting at the Expo is an incredible opportunity to showcase our work to a global audience. Since we have overseas offices as well, we see it as a great chance to expand our presence internationally.

The “TOMO” in PAINTOMO carries the meaning of “together with friends.” This project could only come to life through the support of our partner companies. That’s why raising awareness is so important, and in that sense, the Expo is the perfect stage.

— Finally, what kind of impact do you hope algae-based paints will have on society and the future?

Mr. Akimoto –Research and Technical Development, Musashi Paint HD:

I hope algae will become a completely ordinary material in the future. Swapping out existing products with natural alternatives, while reducing environmental impact, is a crucial first step toward building a sustainable society.

Mr. Oshima – Application Development, CHITOSE:

Bio-based paints actually are extremely important. Unlike plastics, which can be collected and recycled, paints, once applied, can’t be recovered. If they’re petroleum-based, they usually end up being incinerated, emitting CO₂. But if the paint is bio-based, there’s potential for it to be carbon neutral. That’s why I hope we reach a future where materials like algae become the ordinary, not the exception.

— A new material like algae has the power to transform the colors of our society, especially when we move forward together. If PAINTOMO represents the first step on that journey, we couldn’t be more thrilled. We look forward to continuing to shape a vibrant, algae-colored future with all of you at Musashi Paint.

Written by Natsuho Konno / Translated by Tanya Topolian